CNC is an acronym people use to represent Computer Numerical Control. It is a device that is used to curve out designs to detailed precision. Many people confuse CNC devices with 3D printers. However, the difference is that the precision on a CNC device is clinical. To find quality CNC machining, you have to be vigilant. CNC machining tools are costly, and this is why you need to do ample research on how to find the best manufacturer. Below is a list of things to consider if you want an easy time finding a reputable producer.

Know What You Want

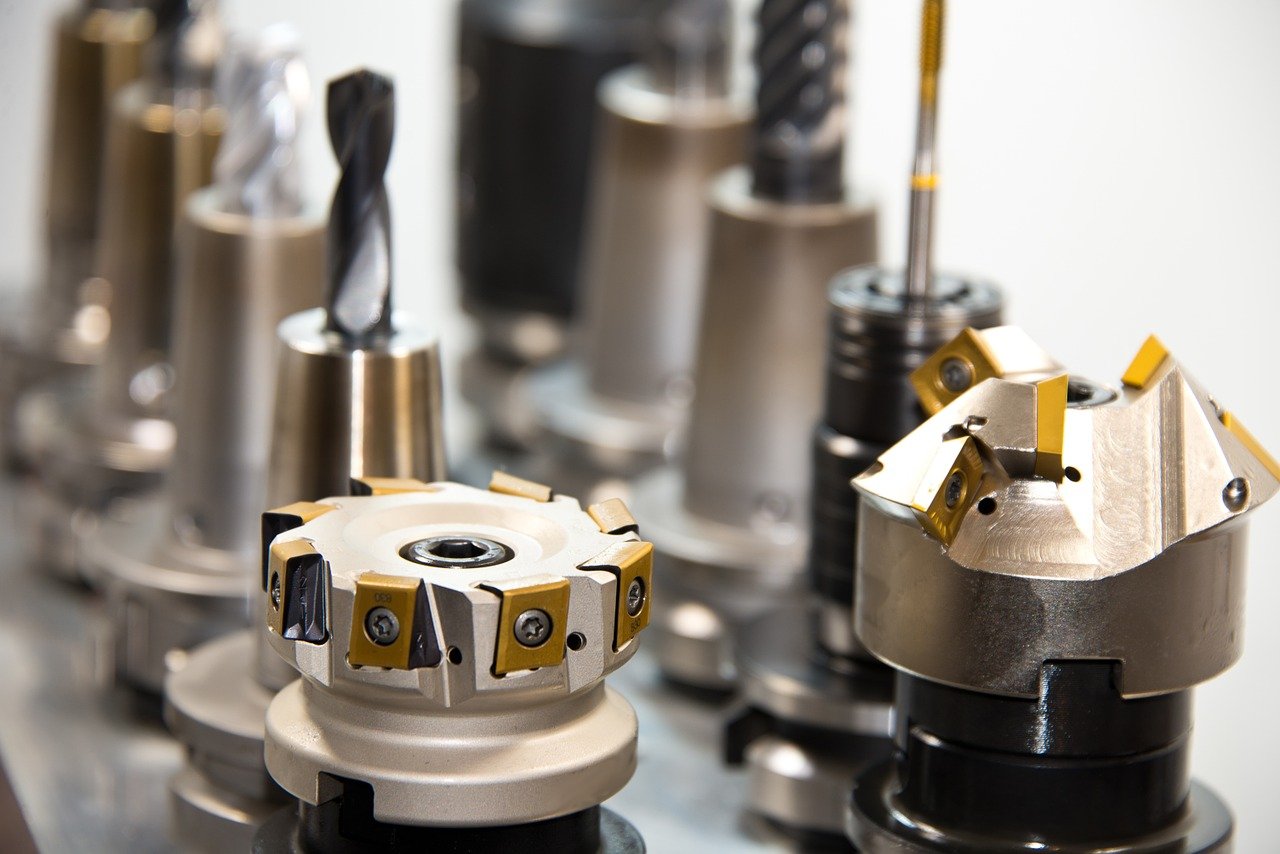

Having predetermined specifications of the type of CNC machine you want will save you a lot of time and effort. The wide range of options includes; drills, lasers, water cutters, and plasma cutters. The cutters use different mediums to cut through materials such as water and plasma. You can consult an engineer in the field you want to invest in for a better understanding.

Research

Research is a key component in getting the best manufacturer in the market. Thanks to the internet, you can find information to help with your search, like specific keywords. Search for them on all social media and search engines as you record notes. After having a general understanding, be sure to call the potential manufacturers you have pinpointed and engage with them. Do a feasibility study and ask them all kinds of questions such as energy requirements and size.

Weigh Your Options

Once you settle on a few potentials, weigh your options, evaluating where you are likely to get the best deal for a CNC. You can base your decision on price point, customer service, warranty, after-sell customer reviews, and even proximity to where you want your machine delivered.

Read Reviews

Reviews are one of the most candid opinions regarding a product. When you read reviews on a company that sells what you want, you know what to expect. After analyzing feedback, you can get the general feel of the company and what it stands for. It’s advisable to stay away from companies that have terrible scores on review charts.

Once you have your eye on the price, consider doubling down your efforts on purchasing the CNC. Depending on your finances, you can finance the purchase with debit or cash. It’s best to finance it with debt because banks and other lending institutions have good rates for people purchasing industrial equipment for development.